Real-time Manufacturing Execution Systems

Manufacturing Data Acquisition Systems

Directional Consulting has a strong history of designing, developing, and deploying manufacturing data acquisition applications. Our strengths include the development of rich pattern detection and normalizing various file patterns and data constructs, which permits multiple file sets to combine as one data set for any assembly line product.

Manufacturing Traceability

Many manufacturing companies sometimes have extended warranty periods of 10 or 25 years. Our proven techniques for reassembling unique data structures and distributed file sets for each assembly production stage provide the necessary traceability. In addition, the industry-standard OLAP (Online Analytical Processing) database design provides a time, location, and value for every single data cell and correlates it into master tables. Any organizational unit can analyze the master tables by selecting the columns of interest and creating detailed reports.

Device Control Systems

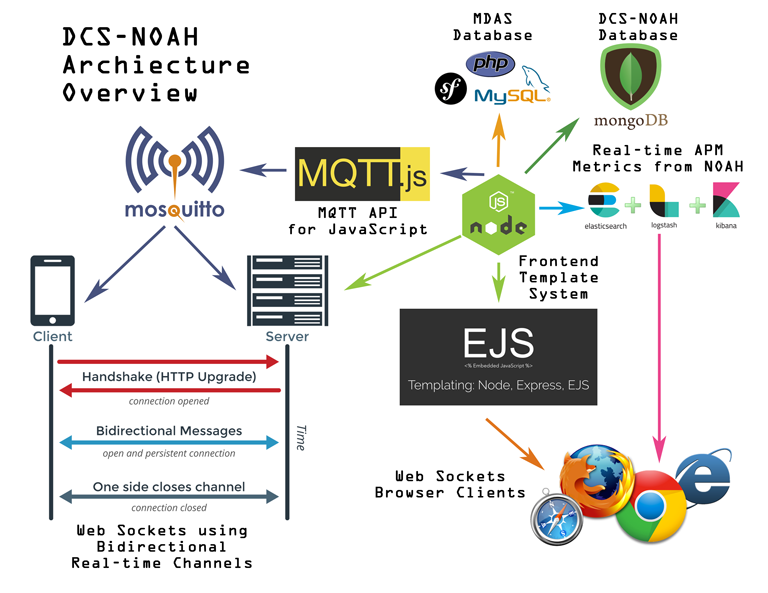

In today's IoT-connected devices and applications, there are many challenges to real-time performance and eliminating latency. Directional Consulting has solid experience working with low-level protocols and server communication gateways using MQTT and Web Socket protocols. Our specialty is designing handshakes and pattern detection to leverage the application's specific needs and the connected hardware.

Real-time IoT Device Information

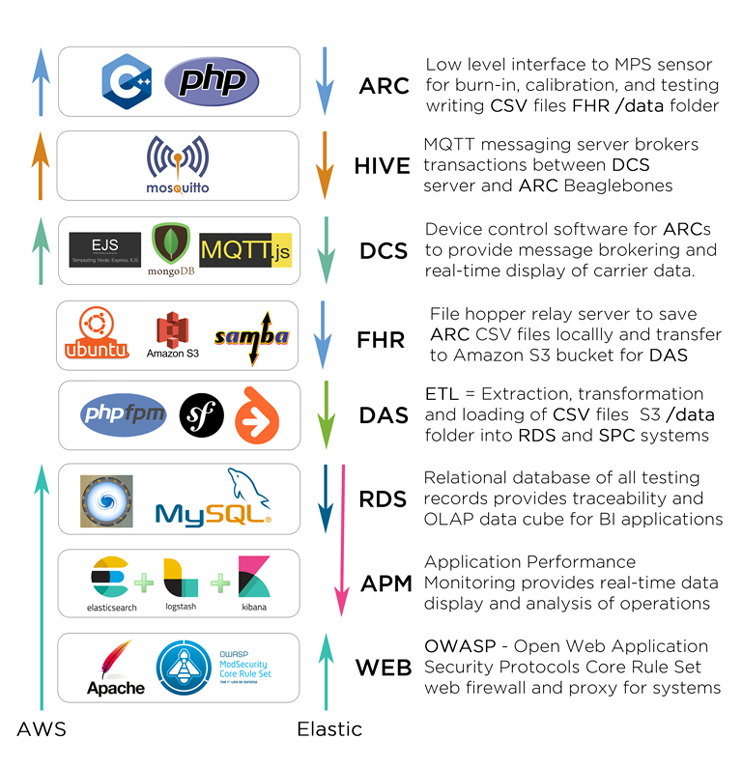

Shown to the right is a high-level overview of a manufacturing execution system with automatic data acquisition. The real-time component is built with Node.JS, MongoDB, MQTT, and Web Sockets to facilitate bi-directional communication with all the devices attached. In addition, there is a connection from the frontend MES software to the backend ETL engine running PHP and MySQL to provide correlated master reports.